Here at Abrading Methods, Inc., we specialize in providing top-notch flat honing services that deliver superior precision and exceptional surface finishes. Since the introduction of flat honing in the late 1980s, this advanced precision fine-grinding process has set a new standard in achieving unparalleled quality in metalworking. Our professional honing services are designed to offer faster stock removal rates and finer finishes compared to traditional grinding, lapping, and honing methods.

What is Flat Honing?

Flat honing is an advanced fine-grinding technique that achieves a remarkable surface finish with a high stock removal rate. This process differs significantly from conventional grinding and lapping by using a specialized abrasive surface that enhances the precision of the finish. Unlike traditional methods that may compromise the surface quality or fail to meet stringent tolerances, flat honing ensures that each part meets the highest standards of accuracy and smoothness.

One of the primary benefits of our flat honing services is the ability to achieve extraordinary levels of precision. Our state-of-the-art equipment allows us to meet the following tolerances:

- Size: ±.000050″

- Flatness: .0001″

- Parallel: .0001″

- Finish: 8 Ra

These exacting standards make our honing services ideal for applications requiring meticulous precision and fine surface finishes. Whether you’re dealing with parts that need high stock removal or precise tolerances, our flat honing capabilities ensure that even the most minute specifications are met with the utmost accuracy.

Typical Applications for Flat Honing

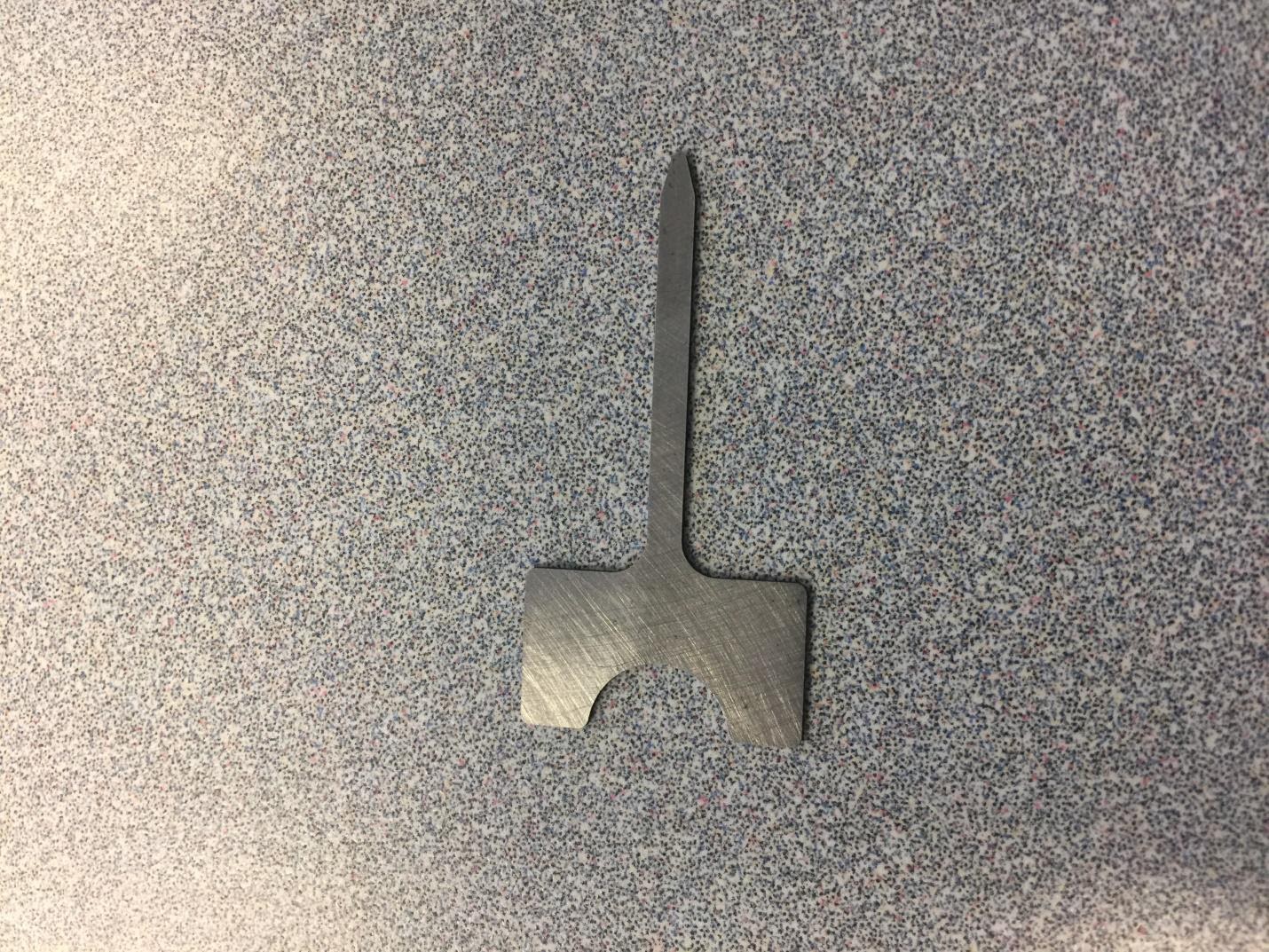

Our flat honing services are versatile and suit various industries. We specialize in precision grinding for metal injection molded parts, powdered metal (sintered) parts, and seals, delivering exacting tolerances and smooth finishes. Our expertise also extends to valve components, carbides and cutting inserts, and precision piston rings, enhancing performance and durability. We also provide high-precision finishing for automotive sensing devices and hydraulic gear pump components, ensuring optimal functionality and reliability across diverse applications.

Our experience extends to a variety of challenging projects. For instance, we have successfully performed flat honing on Heat-Treated Titanium Parts and Tool Steel Parts. These examples highlight our ability to handle diverse and complex requirements with our flat honing expertise.

Why Choose Abrading Methods, Inc.’s Flat Honing Services?

When you choose our honing services, you’re partnering with a company committed to excellence. Our flat honing process combines advanced technology with skilled craftsmanship to deliver superior results. We focus on providing high-quality, precise finishes that other grinding methods may not achieve. Our experienced team ensures that every project meets the highest standards of quality and precision, tailored to your specific needs.

Our willingness to customize shipping is something that sets us apart. We will ship in large batches or multiple small releases depending on the customers’ needs. We will also package the finished components to ensure it is protected from damage and deterioration. We understand the importance of timely and safe delivery, and we strive to exceed your expectations in all aspects of our service.

Ready to experience the benefits of professional flat honing? Contact us today or request a quote and learn more about how our honing services can enhance your projects. Reach out to our team for expert advice, personalized service, and exceptional quality.